Hydraulic Press Machine

Description:

Hydraulic press machine uses liquid as working media which can spread energy to achieve processing work, like bending, shaping, flanging etc. The machine consists of main frame, power system and hydraulic control system. Our company is a professional supplier of press machine in China.

Note:

Custom-made hydraulic press machine is available. Our

Application:

Hydraulic press machine is widely used in processing centric load parts, like bending, shaping, flanging etc. It also can be applied in piercing and blanking processing after it is equipped with device for punching and buffering. Hydraulic press machine is the first choice of shipbuilding industry, pressure vessel industry and chemical industry etc.

Features:

1. Slight deformation

The main frame of hydraulic press machine is featured by excellent rigidity and slight deformation because it adopts frame structure.

2. Hydraulic system adopts differential circuit and it is energy-saving.

3. Reliability

The main frame of hydraulic press machine is equipped with many security facilities to make it safe and reliable.

4. The system supports a device which can absorb hydraulic impact. It can reduce hydraulic impact and ensures the production stable and reliable.

5. Hydraulic system is equipped with low-pressure protection facilities, to prevent damages caused by collision and insertion.

6. It supports PLC control and human/machine interface to make operation easy and simple.

7. Hydraulic press machine adopts remote control to open and lock mold.

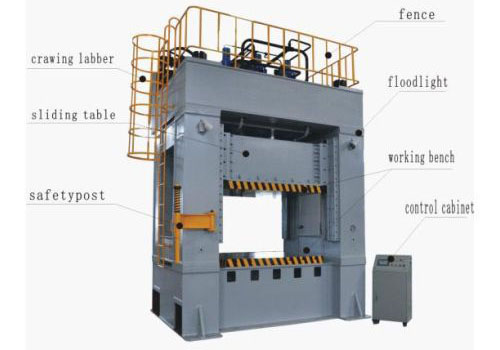

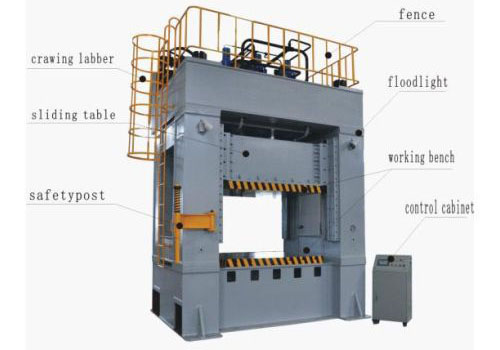

Components:

Parameter:

|

Model

|

Max spotting force

(T)

|

Max lifting force (T)

|

Die opening force (mm)

|

Working bench (mm)

|

Bearing capacity of upper working bench (T)

|

Bearing capacity of lower working bench (T)

|

Suction force of upper magnetic disk(T))

|

Suction force of lower magnetic disk(T))

|

Eject capacity(T)

|

Eject stroke(mm)

|

Out stroke of lower working bench(mm) (mm)

|

Motor power(KW))

|

Total height of machine(H)(mm)

|

Weight of machine(T)

|

|

NCY-500

|

500

|

100

|

1150

|

1800X1500

|

∕

|

∕

|

80±10

|

<25

|

∕

|

∕

|

∕

|

22.0

|

5200

|

32

|

|

NCY-50

|

50

|

20

|

1100

|

1000X700

|

1

|

3

|

70±10

|

<25

|

3

|

100

|

1600

|

5.5

|

3840

|

6.5

|

|

NCY-70

|

70

|

20

|

1100

|

1000X700

|

1

|

3

|

70±10

|

<25

|

3

|

100

|

1600

|

5.5

|

4160

|

6.5

|

|

NCY-100

|

100

|

45

|

1300

|

1300X1000

|

3

|

8

|

70±10

|

<25

|

3

|

100

|

2200

|

7.5

|

4250

|

12

|

|

NCY-120

|

120

|

45

|

1300

|

1300X1000

|

3

|

8

|

70±10

|

<25

|

3

|

100

|

2200

|

7.5

|

4650

|

12

|

|

NCY-150

|

150

|

60

|

1400

|

1500X1100

|

5

|

12

|

70±10

|

<25

|

3

|

100

|

2400

|

11

|

5150

|

18

|

|

NCY-200

|

200

|

80

|

1800

|

1800X1300

|

8

|

20

|

70±10

|

<25

|

5

|

100

|

2800

|

15

|

5680

|

25

|

|

NCY-300

|

300

|

80

|

2100

|

2500X1800

|

12

|

40

|

70±10

|

<25

|

12

|

200

|

4000

|

22

|

7040

|

50

|