| Type | NCS1300 deep hole processing machine |

| Bore of drill hole | φ3-30mm |

| Maximum depth of one-off drill hole | 1300mm |

| Dimension of work platform | 950x1400mm |

| X axis stroke | 1300mm |

| Y axis stroke | 1000mm |

| Z axis stroke | 1350mm |

| Rapid feeding | 4000mm/min |

| Maximum rotary sped of spindle | 6000rpm |

| Spindle power | 7.5kw |

| XYZ servo motor power | 3kw/3kw/1.5kw |

| Pressure of cutting oil pump | 100kg/cm2 |

| Oil pump capacity of oil hydraulic pump | 8-42L/min |

| Capacity of cutting oil tank | 400L |

| Load weight of work platform | 7000kg |

| Net weight of equipment | 11000kg |

| External size of machine tool | 5400x4100x2900mm |

| Total power | 35kw |

| Numerical control system | MITSUBISHI |

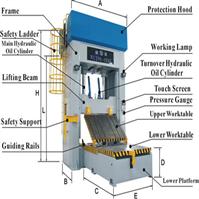

Tag: 120T Vertical Die Spotting Press | 120T Vertical Die Spotting Machine | 120T Die Spotting Press | 120T Die Spotting Machine

Tag: Magneto Electric Die Spotting Press | Magneto Die Spotting Press | Electric Die Spotting Press | Magneto Mold Spotting Press