Description:

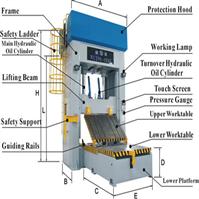

The horizontal mold spotting machine is usually applied for adjusting and maintenance of mold. The series NCW-70 is a newly-developed machine by our company. The mold can turn from 0°-90 °.And it is mainly used for medium and small size mould. The delay protection function of NCW-70 horizontal mold spotting machine ensures the moulds without burrs. Our company is a leading manufacturer of die spotting press in China.

Application:

NCW-70 horizontal mold spotting machine is used in repairing and assembling of various plastic moulds, or metal die-casting dies.

Features:

1. High precision

NCW-70 horizontal mold spotting machine adopts vibration-absorption facility, to reduce hydraulic impact and ensure precision of facilities.

2. Low-pressure protection facility

Hydraulic system is equipped with low-pressure protection facility, to prevent damages caused by collision and insertion.

3.Good effect of red lead

Good effect of red lead can be achieved because of high-speed die spotting.

4. Complete safety facilities

NCW-70 horizontal mold spotting machine is equipped with many safety devices to ensure men’s security, like safety grating, anti-falling oil cylinder, locking cylinder and safety supporting frame and other prevention facilities.

Parameter:

|

Max pressure

|

NCW-70 horizontal mold spotting machine

|

|

Die opening space

|

1250mm

|

|

Max stroke

|

1000mm

|

|

Max capacity size

|

600x600mm

|

|

Fast forward / Fast backward speed

|

70mm/s

|

|

Tool feed speed / Slow feed speed

|

<25mm/s

|

|

Electric permanent magnetic force

|

27T

|

|

Turnover capacity

|

1T

|

|

Angle

|

0-90degree

|

|

Motor power

|

5.5kw

|

|

Machine size

|

1000x1000x4200mm

|

|

Machine total weight

|

6T

|