Die spotting press

Summary:

Die spotting press, or a die spotting machine is applied in mould spotting work. Besides, it's also used in primitive spotting work for small-scale production. After spotting and pressing, it will move lower die out, then move upper die out. Then, the staff technician can fit the faying surface of mould safely. Die spotting press is classified into vertical die tryout press and horizontal die spotting machine.

Types:

-

-

Vertical Die Spotting Machine

-

NC vertical die spotting machine is widely used in repair or verification of mold and it is suitable for medium ...

-

-

Horizontal Die Spotting Machine

-

The horizontal Die spotting pressis widely applied in adjusting and maintenance of mold. The mold can turn from 0°-90°...

It is classified into two types, vertical die spotting machine (NC Series) and horizontal die tryout press (NCW Series).

1. Vertical Die spotting press (NC Series)

2. Horizontal die tryout press (NCW Series)

Application:

Die spotting press is applied in verification of dies and molds. Their dimensions are defined according to the die or mold to be verified. Generally speaking, the required force is lower than in production presses as it needs to check the interface between the upper and lower parts or the die.

Advantages:

1. Core hydraulic pressure source

It confirms the operation of each hydraulic cylinder equipped onto metal die.

2. Light beam safety device

Installing sensors on the front and back side of the press will prevent accidents caused by carelessness and mistakes.

3. Digital position control unit

Die spotting press can digitally control position of slide via encoder while displaying.

4. High efficiency and good quality

Characteristics:

1. Hydraulic die spotting machine is equipped with servo controlled micro-inching system.

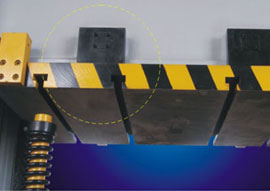

2. No damage to die

Die spotting press is able to make quick response in regards to guiding and stopping position so that cutting punchers of one side wouldn’t damage the other side of the die.

3. Tilting device

Mold isn’t fast enough to guide. However, the idea that man adds tilting devices in both slide and bolster can improve efficiency of the skilled workers who are fitting the mold.

4. This Die spotting press is equipped with special devices such as slide stop which can stop the platen at any point within stroke, electrically interlocked safety block, and so on.

5. Easy operation and safety

Die spotting machine can also relieve the operator’s tension and fatigue to ensure the safety of die press operations because of machine/human interface and convenient operation.

6. Every Die spotting press is equipped with security facilities.

Anti-falling facilities

Anti-falling facilities Locking facilities

Locking facilities

Safety supporting facilities

Safety supporting facilities Rating protection

Rating protection

Related Pages

Work Flow of Die spotting press | Inspection Method of Die Spotting Machine

Anti-falling facilities

Anti-falling facilities Locking facilities

Locking facilities

Safety supporting facilities

Safety supporting facilities Rating protection

Rating protection