Description:

Vertical NC300F-2015 180° mold spotting press is widely used in adjustment or verification of mold or die. With spotting force: 300T, working bench: 2000×1500mm, it is especially fit for middle and large mould. Compared with traditional die tryout press, vertical NC300F-2015 vertical die spotting press adopts electric magnetic chuck, thus it can save time and can improve work efficiency. The moulds can be turned around 0-180. Additionally, it is easy and reliable to use NC300F-2015 180° mold spotting press with computer control and man/machine interface.

Features:

1. Core hydraulic pressure source confirms the operation of each hydraulic cylinder equipped onto metal die.

2. Low energy consumption

Vertical NC300F-2015 180° mold spotting press will greatly reduce energy consumption and exhaust heat, compared with traditional methods through inverter control of the main electric motor.

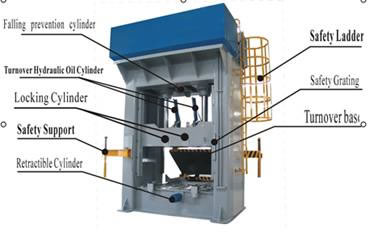

3. Perfect safety facilities.

There are many safety facilities to ensure men’s security, like safety grating, anti-falling oil cylinder, locking cylinder and safety supporting frame and other prevention facilities.

4. High precision

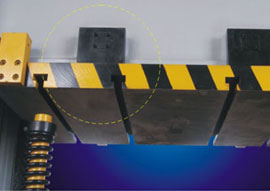

Vertical NC300F-2015 180° mold spotting press has high precision because hydraulic system adopts vibration-absorption facilities which will reduce hydraulic impact.

5. Hydraulic system is equipped with low-pressure protection facilities, to prevent damages caused by collision and insertion.

6. The 180° mold spotting press is equipped with security facilities.

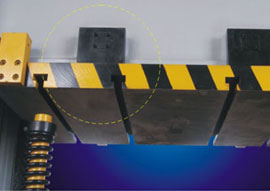

Anti-falling facilities

Anti-falling facilities Locking facilities

Locking facilities

Safety supporting facilities

Safety supporting facilities Rating protection

Rating protection

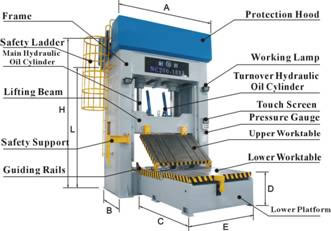

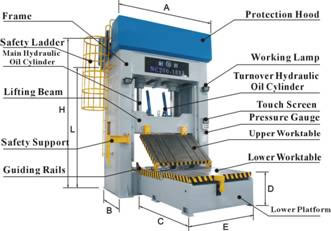

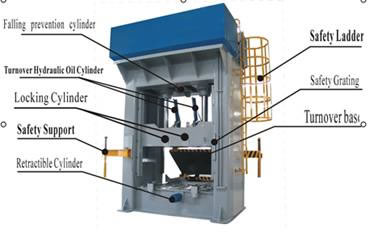

Components:

Front view

Front view Side view

Side view

Parameter:

|

Model

|

Vertical NC 300F-2015 180° mold spotting press

|

|

Max spotting force(T)

|

300

|

|

Max lifting force(T)

|

80

|

|

Die opening space(mm)

|

1800

|

|

Size of working bench(mm)

|

2000×1500

|

|

Bearing capacity of upper working bench(T)

|

8

|

|

Bearing capacity of lower working bench(T)

|

20

|

|

Suction force of upper magnetic disk(T)

|

180

|

|

Suction force of lower magnetic disk(T)

|

80

|

|

Fast up/down speed(mm/s)

|

70/70

|

|

Slow up/down speed(mm/s)

|

<25

|

|

Eject capacity(T)

|

5

|

|

Eject stroke(mm)

|

100

|

|

Out stroke of lower working bench(mm)

|

3200

|

|

Motor power(KW)

|

22

|

|

Total height of machine(H)(mm)

|

6250

|

|

Land area of machine(mm)

|

6600×5800

|

|

Weight of machine(T)

|

35

|

If you need more information about vertical mold spotting machine, please click Quick links:

Inspection Method of Die Spotting Machine | Work Flow of Die spotting press

Anti-falling facilities

Anti-falling facilities Locking facilities

Locking facilities

Safety supporting facilities

Safety supporting facilities Rating protection

Rating protection

Front view

Front view Side view

Side view